Make Your Mark with Plastisol Inks- The Ideal Choice for Custom Apparel and Promotional Products

| Feb, 07 , 23

Screen printing is a popular method of producing high-quality designs on various custom items, including clothes, ceramics, metals, and more. One of the most commonly used inks in screen printing is plastisol, a type of ink created from a mixture of PVC resin and plasticizers. We know plastisol inks for their vibrant colors, durability, and versatility, making them a popular choice for custom items. Whether you’re starting a business, creating custom apparel for a group or event, or looking to promote your brand, plastisol inks can provide a high-quality, cost-effective solution.

Screen printing inks:

There are several types of inks used in screen printing custom items, including:

- Plastisol ink is the most commonly used ink in screen printing. They make them from PVC particles suspended in a plasticizer, which gives them a thick, opaque, and vibrant appearance.

- Water-based inks are more environmentally friendly than plastisol inks and produce a soft, breathable print. They are ideal for printing light-colored custom merch. We can clean them with water.

- Discharge inks help print on dark garments and work by removing the dye from the fabric, leaving only the print behind. The result is a soft, comfortable print that becomes one with the garment.

- Hybrid inks are a mix of plastisol and water-based inks that combine the best of both worlds. They offer the opacity and vibrancy of plastisols while still being environmentally friendly and producing a soft print.

- Solvent-Based inks are made from volatile organic compounds (VOCs) and help print on plastic, metal, and glass. We do not generally use them for printing on apparel.

- UV-Curable inks use ultraviolet light, which hardens the ink and makes it resistant to fading and washing. They are ideal for printing on a variety of surfaces, including plastics, metals, and glass, as well as textiles.

What are plastisol inks and their benefits?

Plastisol is a type of ink commonly used in screen printing. They make it of PVC particles suspended in a plasticizer, which gives it a thick and sticky consistency. It makes it suitable for printing onto custom merch and other porous surfaces, as it does not penetrate the material and forms a smooth, opaque layer.

Plastisol is popular in screen printing because of its versatility, ease of use, and ability to produce bright and vibrant prints.

Plastisol inks offer several benefits in screen printing custom merch:

- Opacity: Plastisol inks are opaque and produce bright, vibrant prints easily visible on light and dark materials.

- Versatility:We can use Plastisol inks on a wide range of materials, including cotton, polyester, and nylon, making them a popular choice for screen printers.

- Easy to Use:Plastisol inks are simple and do not require special equipment or extensive arrangements. They can be easily mixed to create custom colors and are stable when stored for long periods.

- Durability:Plastisol inks are heat-cured, which makes them durable and resistant to fading and washing. It is ideal for printing custom items for long-term use.

- Cost-Effective:Plastisol inks are cost-effective and offer a high level of print quality at a reasonable price. It makes them a popular choice for businesses looking to maximize their profits.

- Consistent Results:Plastisol inks produce consistent results and are less prone to issues such as poor adhesion, cracking, or yellowing, compared to other types of inks.

Plastisol v water-based inks:

Plastisol and water-based inks are both used in screen printing, but they have several key differences:

Plastisol Inks:

- Made of PVC particles suspended in a plasticizer

- Opaque and produce bright, vibrant prints

- Versatile and can be used on a wide range of materials

- Easy to use and store

- Durable and resistant to fading and washing

- Cost-effective

- Not environmentally friendly

Water-Based Inks:

- Made with water as the main component

- Produce a soft, breathable print

- Ideal for printing on light-colored garments

- Environmentally friendly and easy to clean up with water

- Mild and less vibrant compared to plastisol inks

- It can be more challenging to use, with a longer curing time and requiring specific equipment

The choice between plastisol and water-based inks depends on the specific requirements. Plastisol inks are more versatile and cost-effective, while water-based inks are environmentally friendly and produce a softer print.

How to use plastisol inks for printing custom apparel and accessories?

Here is a basic outline of how to use plastisol inks for screen printing:

- Prepare the Screen: The manufacturer cleans it and attaches it to the printing press. It ensures it is free of any residue or debris.

- Mix the Ink: Plastisol inks come pre-mixed, but they adjust the consistency or color as needed. To do this, they mix the ink with a stir stick or a paint mixer attached to a drill.

- Load the screen: They pour the ink into it and disperse it using a squeegee. It fills the entire screen and removes any air bubbles.

- Printing:They position the garment or substrate under the screen and align it with the printing area. The manufacturer uses the printing press to press the squeegee down the screen and onto the garment, applying consistent pressure. They repeat the process for each color in your design.

- Curing:Plastisol inks require heat-curing to harden and bond to the garment. They typically do this in a conveyor dryer or flash cure unit. The exact curing time and temperature depend on the material and ink.

- Clean-Up:They clean the screen and ink residues as soon as possible to avoid drying and hardening. The manufacturer uses a solvent-based cleaner specifically designed for plastisol inks.

Note: We recommend you follow the manufacturer’s instructions and guidelines for using plastisol inks, as different inks may have specific requirements and limitations. Also, test it on a sample garment before starting the production run to ensure they achieve the desired results.

What are the items we can customize using plastisols?

Plastisol inks can print on a wide range of fabrics and apparel, including:

- Custom t-shirts: Plastisol is a popular choice for printing on t-shirts because of its versatility and ability to produce bright and vibrant prints.

- Custom hoodies and sweatshirts: Plastisol inks work well on thicker, heavier fabrics like fleece, making them an option for printing hoodies and sweatshirts.

- Custom athletic wear:We often use Plastisol inks for printing on performance wear and athletic apparel because of their durability and resistance to fading and washing.

- Custom tote bags and accessories: We can also use Plastisol inks for printing on bags, hats, and other accessories.

- Custom workwear: Plastisol inks are a popular choice for printing on workwear, such as uniforms and safety gear, because of their durability and resistance to fading and washing.

- Custom promotional products: We often used Plastisol inks for printing promotional products, such as water bottles, key chains, and other items.

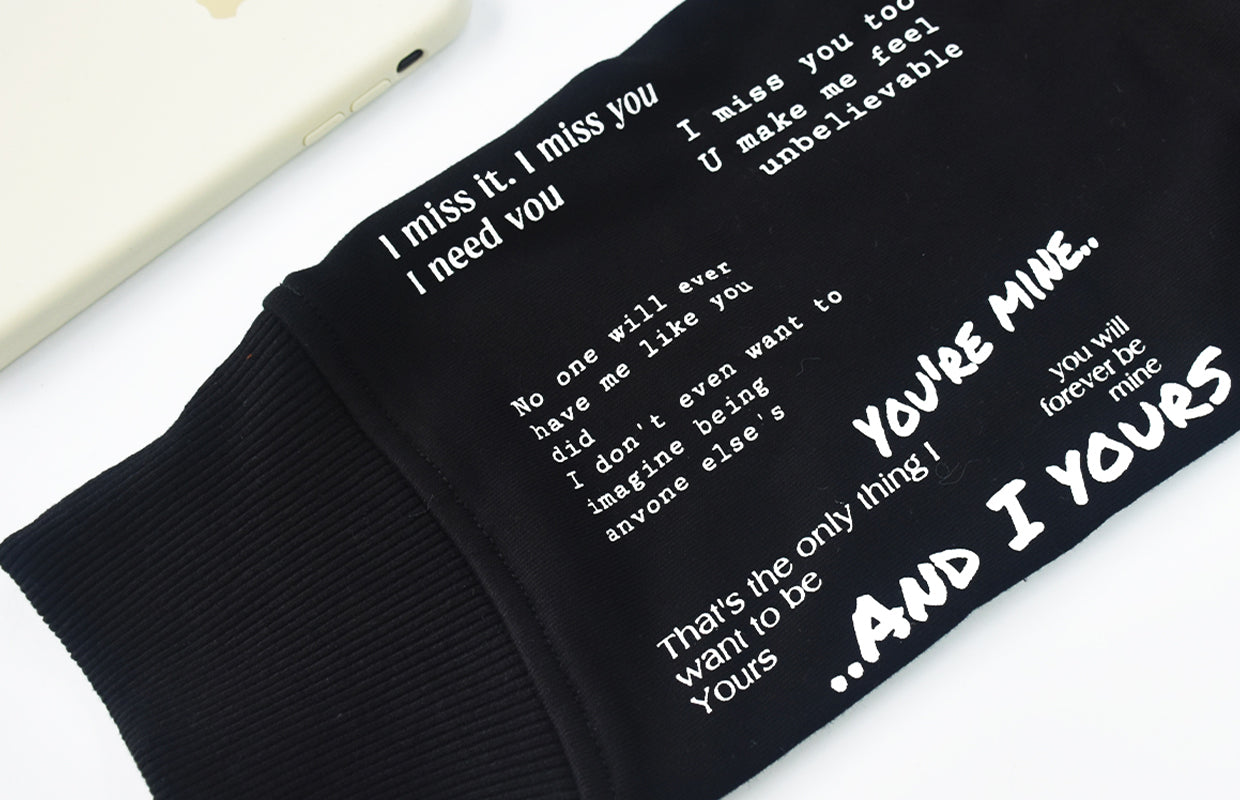

- Custom socks:We can also use it for customizing socks, but it is important to note that plastisol ink can sometimes be uncomfortable on the skin and might not be the best choice. Additionally, some people might be sensitive to the chemicals used in plastisol inks.

We can use plastisols on a wide range of fabrics and apparel, including cotton, polyester, and blends of both. It will affect the final appearance and durability of the print, so choose the accurate fabric for the specific project. A tightly woven, smooth fabric will produce the best results using plastisol ink. It is also important to pre-treat the material to ensure proper adhesion of the ink.

Steps of plastisol printing:

Preparing artwork for plastisol printing involves several steps to ensure that the final print will look as desired:

- Design creation: Start by creating your design in vector-based software, such as Adobe Illustrator or CorelDRAW. They prefer vector graphics for screen printing as they can use them without losing quality.

- Color separation: If your design has multiple colors, you’ll need to separate the artwork into individual color layers, one for each color to be printed.

- Film output:Once you separate the design into individual color layers, print out films of each layer. They use films to create the stencils for the screen printing process.

- Screen preparation: They burn the film stencils onto the screens using an “exposure unit.” The ink will transfer onto the custom merch, where the stencils define the areas.

- Printing:Once the screens are ready, it’s time to start printing. They pour the ink onto the screen and place the custom merch underneath. The ink is then pressed through the stencil and onto the garment using a squeegee.

- Curing: Plastisol inks require curing at a high temperature, typically around 320°F, to fully cure the ink and ensure that the print will be durable and long-lasting.

- Quality control:Before packaging and shipping the finished product, they inspect each print to ensure that it meets quality standards and looks as desired.

These steps should give you an overview of preparing artwork for plastisol printing. It’s crucial to follow best practices and work with a manufacturer or supplier who has experience with plastisol inks to ensure that the final product is of high quality and meets your expectations.

How to use plastisol printing for brand awareness?

Plastisol printing can be an effective way to raise brand awareness and promote your business. Here are some tips for using plastisol printing to boost brand recognition:

- Choose the accurate garments: Choose clothes that are popular and well-suited for your target audience. For example, if your target audience is active, you may print on performance wear or athletic apparel.

- Customize your designs to include your logo, brand colors, and any other elements that represent your brand. It will help to create a bold and consistent brand image.

- Consider the printing process: Use high-quality plastisol inks and screens to ensure your prints are sharp, vibrant, and long-lasting. Consider printing on multiple areas of the garment, such as the front, back, and sleeves, to maximize exposure and increase brand recognition.

- Use promotional products: Besides printing on garments, consider using plastisol printing to create other promotional products, such as tote bags, hats, and water bottles.

- Partner with influencers and organizations that share your brand values and have a following that aligns with your target audience. Ask them to wear your branded garments and share images on their social media platforms.

- Host events to showcase your brand and distribute your printed garments. It will give people an opportunity to see and experience your brand firsthand.

By following these tips, you can effectively use plastisol printing to raise brand awareness and promote your business.

What are a few common myths about plastisol inks?

There are several common myths about plastisol printing that are often not based in fact. Here are a few:

- Plastisol is not environmentally friendly: While plastisol inks contain PVC particles, we can safely dispose of them, and is not harmful to the environment. However, people consider water-based inks to be more environmentally friendly.

- Plastisol only works on dark fabrics:We can use Plastisol inks on a wide range of materials, including light and dark colors. There are also unique opaque plastisol inks that can be used on dark fabrics to achieve bright, vibrant prints.

- Plastisol is difficult to use:While plastisol inks may require a bit more arrangement and preparation than other inks, they are easy to use once you get the hang of them. Many screen printers prefer plastisol because of its versatility and consistency.

- Plastisol prints are not durable:We know Plastisol inks for their durability and resistance to fading and washing. If properly cured, plastisol prints can last for several years.

- Plastisol printing is expensive:While the initial investment in plastisol printing equipment may be higher than other printing methods, plastisol inks are often more cost-effective in the long run.

It’s important to separate fact from fiction for plastisol printing, as many misconceptions can affect the decisions of businesses.

What are the alternatives for plastisol printing?

Plastisol inks are a popular choice for screen printing, but several alternative inks are also commonly used, including:

- Water-based inks are a popular alternative to plastisol inks, as people consider them more environmentally friendly and produce a soft, breathable print.

- Discharge inks help to print on dark merch and work by removing the dye from the cloth and replacing it with the ink color. This results in a soft, nearly undetectable print.

- Eco-friendly inks are more environmentally friendly than traditional inks. They make them with natural ingredients and pigments.

- High-density inks are thicker than standard inks and are used to create raised 3D-like prints.

- Glitter and metallic inks add sparkle and shine to prints, making them a popular option for special occasions and fashion designs.

These are just a few of the alternative inks that are available for screen printing. The best choice for a project will depend on the desired outcome, fabric type, and printing process.

Over to you:

lastisol inks are a versatile and cost-effective solution for screen printing businesses, graphic designers, and anyone looking to create custom apparel or promotional products. These inks offer a range of benefits, including vibrant colors, durability, and ease of use, making them an excellent choice for a wide variety of printing applications. Whether you’re starting a business or looking to promote your brand, plastisol inks are a reliable and effective option that can help you achieve your goals. With the preparation, techniques, and equipment, you can produce high-quality, long-lasting prints that will help you stand out and make a lasting impression.

How to choose a manufacturer for plastisol printing custom items?

Choosing a manufacturer for plastisol printing can be a crucial decision that can affect the quality of your finished products and the success of your business. Here are some factors to consider when choosing a plastisol printing manufacturer:

- Quality of products:Look for a manufacturer using high-quality materials and a proven track record of producing consistent, reliable results. Consider asking for samples of their previous work to see the quality of their printing.

- Equipment and technology:Ensure the manufacturer has modern, well-maintained equipment for producing the type of prints you need.

- Lead time and delivery: Look for a manufacturer that can meet your delivery schedule and offer flexible lead times. Consider factors such as turnaround time, shipping times, and any additional costs for rush orders.

- Pricing and cost:Compare prices from multiple manufacturers to ensure you get the best value for your money. Consider additional costs, such as shipping and handling, set-up fees, and minimum order quantities.

- Customer service and support:Look for a manufacturer that offers responsive, knowledgeable customer service and support. Consider their communication skills and willingness to work with you to resolve any issues that may arise.

- Reputation and reliability:Consider the manufacturer’s fame in the industry, experience, and customer reviews. Look for a reliable, trustworthy, and proven track record manufacturer of producing high-quality prints.

Considering these factors, you can choose a plastisol printing manufacturer that meets your needs and provides high-quality, reliable results.

Customize high-quality custom items with EverLighten:

EverLighten has helped startups, corporations, sports teams, nonprofits, hospitals, celebrities, individuals, etc., for nineteen years.

- Best value: We manufacture custom items in our factory, which helps you to get the best cost in the industry.

- Top quality: Customers get items with the best materials, processes, and packaging.

- Quick delivery: EverLighten delivers every project in the least time.

- Comprehensive support: You can contact the customer help team anytime.

- Customer-first: We love helping people and accept every order.

- 100% customization: Customers can customize every aspect - materials, colors, size, artwork, shape, printing process, etc.

- Low order requirement: We offer the lowest minimum order quantity in the industry.

- Worldwide delivery: EverLighten delivers to every part of the globe, and customers can track their orders with an online tool.

For more advice, inspiration, and ordering, visit https://everlighten.com/.

Tags:

custom products